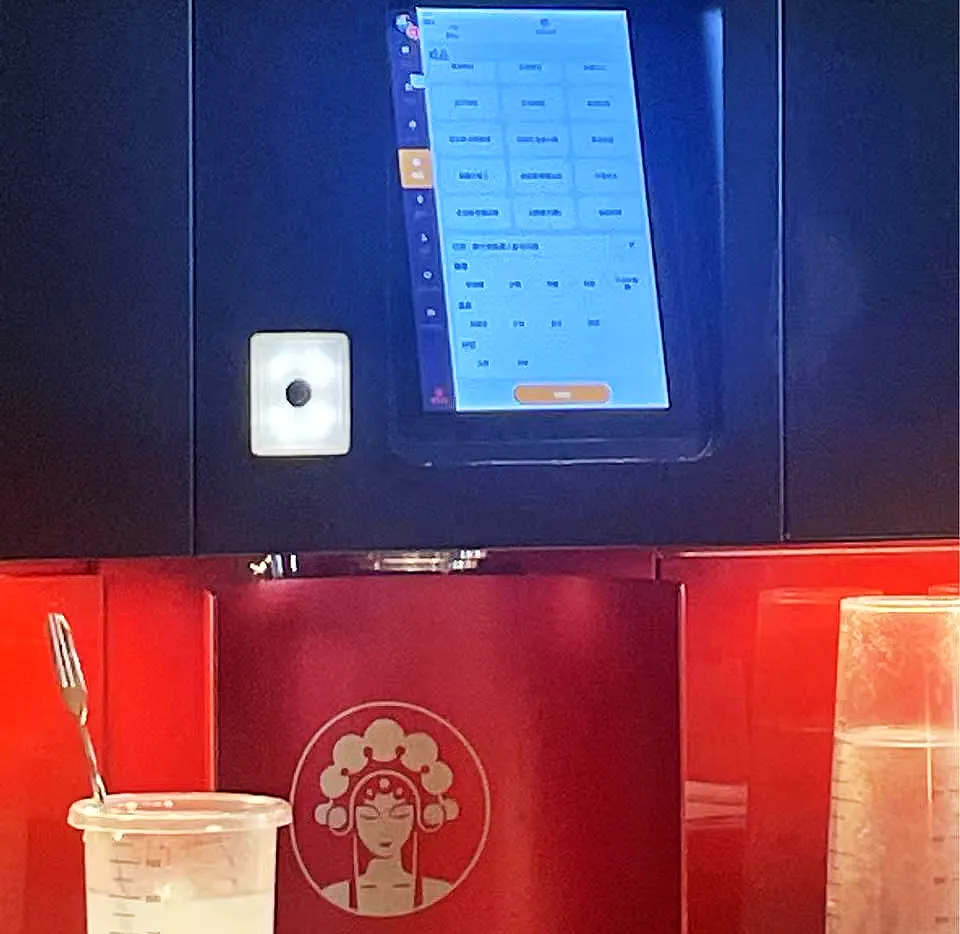

Notably, TEDIA’s intelligent beverage equipment has obtained major global safety and food hygiene certifications, including ETL, CE, CB, FDA, KC, LFGB, UKCA, and PSE, as well as ISO 27001 (Information Security Management) and ISO 20000 (IT Service Management) certifications.

The equipment features intelligent user interfaces supporting Chinese, English, and other major global languages, effectively removing regional barriers and enabling flexible global hiring.

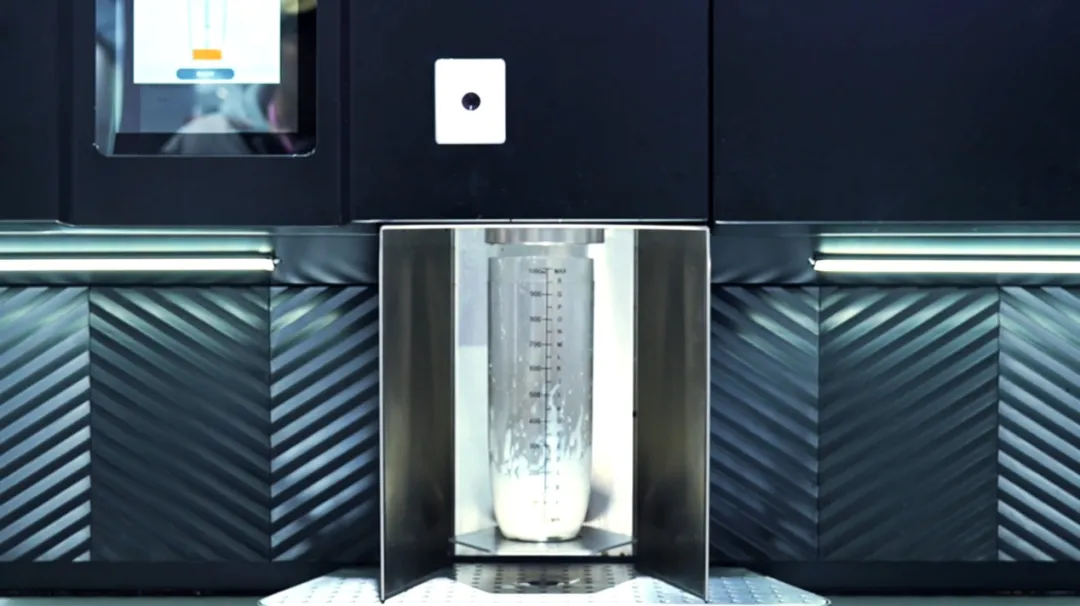

03 Next-Generation Intelligent Equipment on the Way: Technology Infrastructure to Capture Greater Market

As new tea beverage brands expand beyond Southeast Asia into Japan, South Korea, Europe, North America, and the Middle East, the globalization of tea beverages has entered a new stage.

As a representative brand, CHAGEE plans to open 1,000 to 1,500 new stores globally in 2025, with its first North American store launching simultaneously. Funds raised from its U.S. listing will be used for store expansion, product innovation, overseas supply chain development, and digital upgrades.

Against this backdrop, CHAGEE continues to deepen its application of intelligent technology across the entire industry chain.

In its prospectus, the company states that it will continue increasing investment in technology to further enhance automation, standardization, and digital capabilities. Its core strategy is to use intelligent technology as foundational infrastructure to improve efficiency from store operations to the supply chain, ensuring stable flavor profiles and consistent product quality.

According to informed sources, building on the technological foundation of existing intelligent tea-making equipment, CHAGEE is jointly developing next-generation intelligent equipment with its strategic partner, TEDIA.

Meanwhile, TEDIA’s overseas business is expanding rapidly. The company has established strategic partnerships with multiple internationally renowned restaurant and convenience store groups and has entered the phase of large-scale deployment.

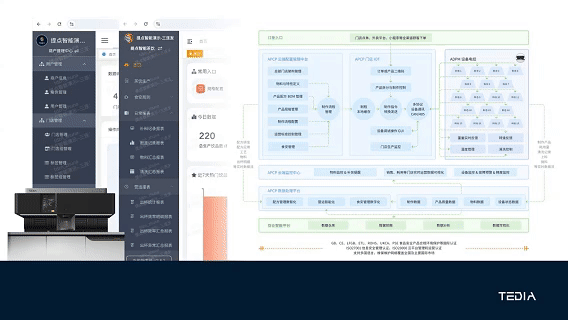

From ingredient traceability to store operations, from new product development to consumer insights, data intelligence is reshaping the industry ecosystem. Particularly in cross-cultural market expansion, intelligent beverage preparation and digital management systems are essential for maintaining consistent quality and efficient operations.

Through its integrated “equipment + system + customer success services” solution, TEDIA is not only enabling chain tea beverage brands to achieve standardization, scalability, and globalization, but also helping Eastern tea reach global markets in a more standardized and modern form.

The globalization of Eastern tea is a shared objective across the new tea beverage industry, and intelligent innovation is the key driver of its continued evolution.

It is increasingly evident that future global market share in freshly made beverages will first concentrate among brands that have successfully completed their technology infrastructure build-out.

返回

返回